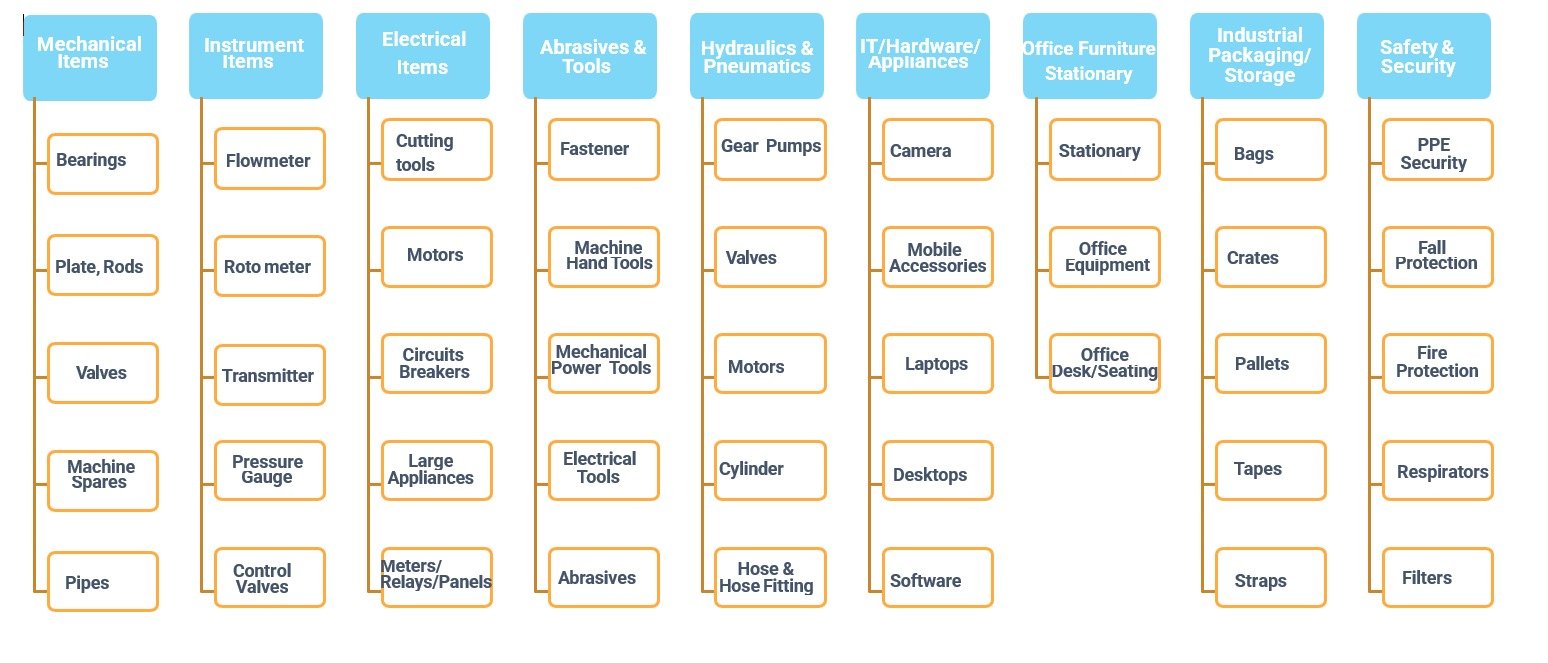

Maintenance repair

and operation spares

When cost and risk reduction matter, the industry chooses Shubhaga

Shubhaga is specialized in supplying of MRO items. If required we could consolidate and supply such spares in effective way and create value for our esteemed clients

What is MRO

Maintenance, Repair, and Operations (MRO) inventory refers to all items necessary for maintenance work and day-to-day operations. Also known as stock control, MRO ensures accurate inventory counts of consumable materials to reduce maintenance downtime and related costs

MRO SOULITONS

Proactive Procurement

We utilize our strategies and well-established MRO relationships helping to facilitate service excellence without compromising on quality.

Vendor Rationalization

We help reduce your suppliers allowing for significant savings on your bottom line. Say goodbye to needing multiple suppliers for similar items.

Dedicated Procurement Manager

Our expertise provides exceptional end-to-end procurement management handled by your dedicated manager.

Cost Savings

Our procurement process will provide a minimum saving of 3% on MRO spend through consolidation and bundling of items.

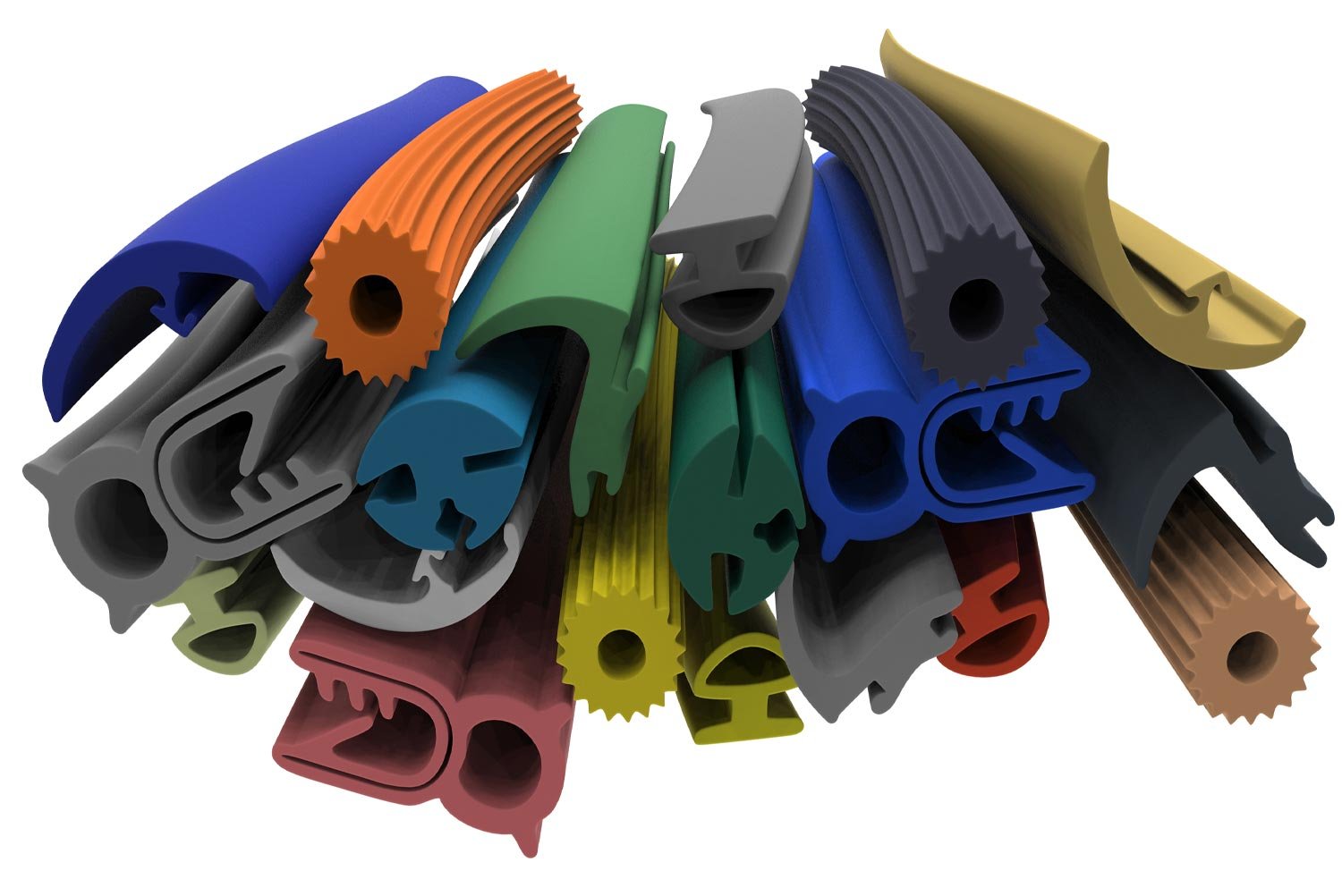

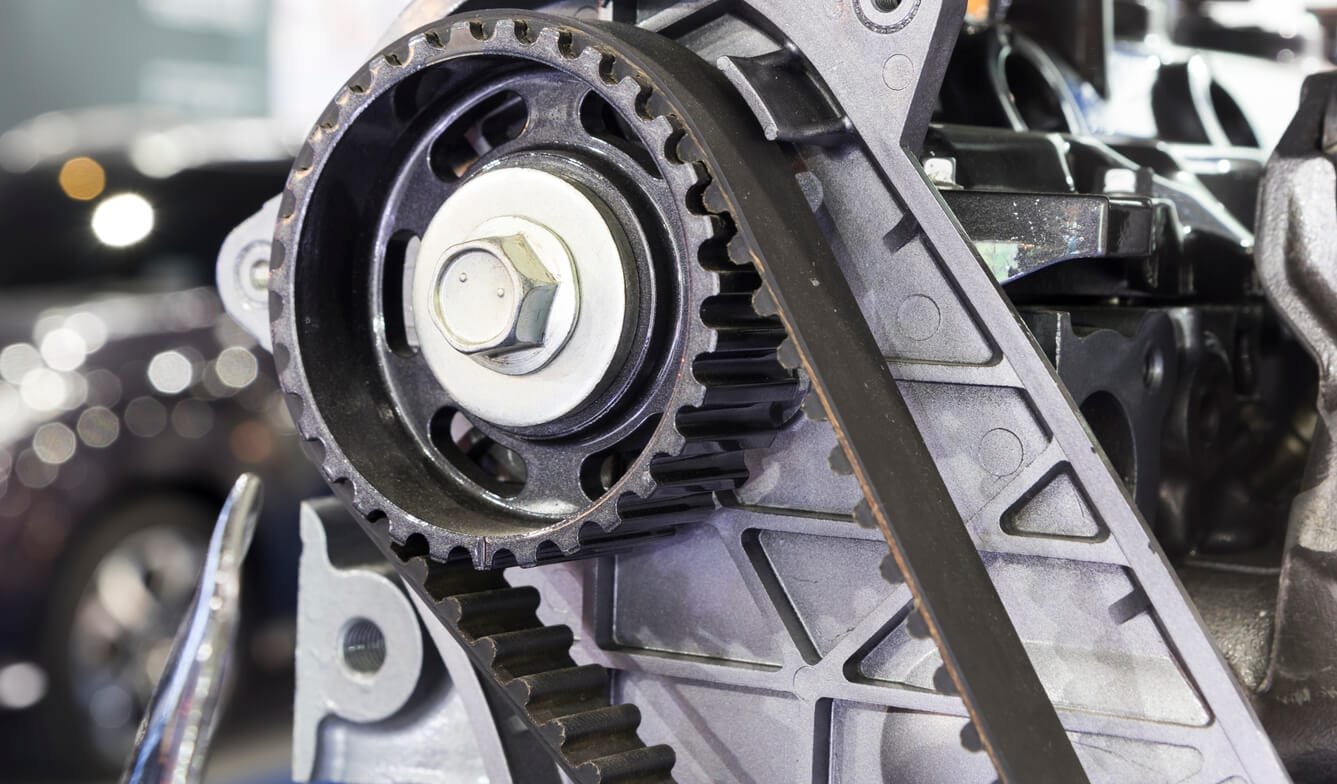

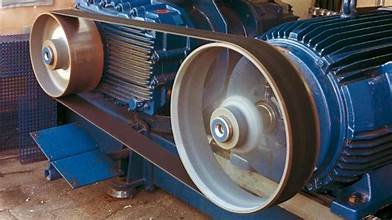

MRO Inventory

MRO inventory is all inventory related to daily operations, onsite repair work, and maintenance tasks. This can range from typical office supplies to highly specialized replacement parts. MRO inventory depends on timely procurement processes to ensure that enough material is ordered for continual operations.

MRO inventory can increase accuracy by letting businesses know which items are over/understocked and only ordering what is necessary. Well-stocked MRO inventory can increase productivity, since maintenance teams won’t have to wait for replacement parts to arrive whenever repairs are needed. Instead, they can simply select from the available stock and get to work.

With a well-maintained MRO inventory, businesses can lower operating costs by only ordering materials when they are needed. Purchasing too many spare parts in advance can lead to overstock and overflowing storage spaces. It can also result in unnecessary expenses if the material never gets used. MRO uses continual counting to determine which items get used the most and which items need to be replaced most frequently.

Common Challenges of MRO

Supplier shortages: MRO’s dependence on suppliers leaves it vulnerable to disruptions, leading to potential shortages.

Duplicate supplies: Excessive ordering creates costly stockpiles, occupying valuable storage space.

Poor forecasting: Inaccurate forecasting can cause understock or overstock situations, resulting in operational downtime.

Worker satisfaction: Trust in the MRO system is crucial, but personal stocks may lead to shortages during critical repairs.

Scalability: Smooth MRO operation demands effort, making it challenging for small businesses with limited needs.